前两天,三川宏磁力泵厂家——川田环保科技为您解析了关于立式泵和电镀过滤机的一些相关知识,解析了一些关于立式泵的组装和使用注意事项,电镀过滤机的过滤原理等内容。接下来我们再来分享三川宏磁力泵MEB系列的相关参数性能。

三川宏磁力泵MEB系列作为ME耐酸碱磁力泵型号的一员,拥有ME磁力泵的所有属性,无轴封设计几乎没有摩擦不易泄漏,可空转运行(耐酸碱磁力泵理论上是都可以空转运行,但在实际的使用过程中,还是不建议空运转。因空转会造成泵内温度升高,内部的陶瓷轴容易因突然吸入溶液由于热胀冷缩应力等原因造成断裂。若发现磁力泵存在空转的情况,应停机10~20分钟,等待其冷却后投入工作。所以说,咱们三川宏厂家是不建议磁力泵空转运行的。)

MEB型号磁力泵一般采用FRPP增强聚丙烯塑料材质一体注塑成型,机械强度高,坚固耐用,由于PP材质,具有不错的耐强酸碱腐蚀性能,常用于输送化工酸碱溶液。具体型号如下:MEB6522,MEB6532,MEB6552等,具体表示耐酸碱磁力泵型号MEB系列,65代表口径DN65,二组数字2、3、5代表马力2马力3马力5马力,后一组数字表示电机极数2极。

MEB系列磁力泵耐药性与三川宏其他系列的化工泵耐药性一样,FRPP材质泵头不可用于铬酸、氢氟酸、wang水等溶液,其他强酸碱溶液视具体浓度和温度使用,详情咨询三川宏客服。

|

型式 model |

口径英寸 in-out |

相数 φ |

级数 P |

功率 HP |

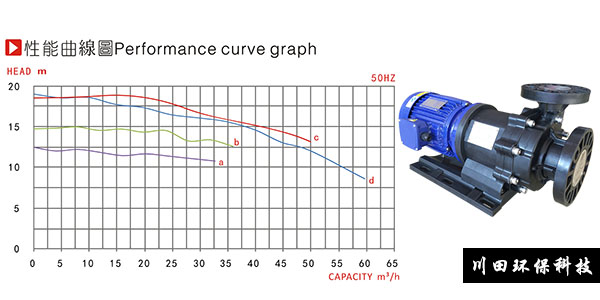

曲线图 |

流量 T/H |

扬程 M |

重量 KG |

| MEB6522 | 2.5X2 | 3 | 2 | 2 | a |

12.5 25 30 |

11.5 11 10.5 |

41 |

| MEB6532 | 2.5X2 | 3 | 2 | 3 | b |

12.5 25 35 |

14.5 13.5 12.5 |

44 |

| MEB6552 | 2.5X2 | 3 | 2 | 5 | c |

12.5 25 40 |

19 17 15 |

48 |

| MEB6552 | 2.5X2.5 | 3 | 2 | 5 | d |

12.5 25 60 |

18.5 16.5 8.5 |

48.5 |

三川宏化工泵、电镀过滤机耐药性一览表

优● 良○ 不良▲ 差X

| 药液 | 浓度 | 温度 | 泵材质 | 轴封材质 | 轴封弹簧 | 橡胶材质 | ||||||

| FRPP | PVDF | Ceramic | Carbon | Sic | SUS316 | HC | EPT | VITON | NBR | |||

| 硝酸 |

20 |

40 |

● |

●

|

●

|

|

●

|

|

● |

|

● |

|

| 60 |

○ |

● |

○ |

|

● |

● |

● |

|

● |

|

||

| 80 |

○ |

● |

|

|

● |

○ |

● |

|

● |

|

||

|

50 |

40 |

● |

● |

|

|

● |

○ |

● |

|

● |

|

|

| 60 |

○

|

● |

|

|

● |

● |

● |

|

● |

|

||

|

铬酸 |

20 |

40 |

|

● |

● |

|

|

○ |

● |

|

● |

|

| 60 |

|

● |

● |

|

|

|

● |

|

● |

|

||

| 80 |

|

● |

● |

● |

● |

|

● |

|

○ |

|

||

| 磷酸 |

25 |

40 |

● |

● |

● |

● |

● |

|

● |

● |

● |

● |

| 60 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

○ |

||

| 80 |

○ |

● |

● |

● |

● |

● |

● |

○ |

● |

|

||

|

50 |

40 |

● |

● |

● |

● |

● |

○ |

● |

● |

●

|

|

|

| 60 |

● |

● |

● |

● |

● |

● |

● |

○ |

●

|

|

||

| 80 |

○ |

● |

○ |

● |

● |

● |

● |

○ |

● |

|

||

| 氢氧化钠 | 45 | 40 |

● |

● |

▲ |

● |

● |

○ |

● |

● |

○ |

● |

| 60 |

○ |

○ |

X |

● |

● |

● |

○ |

● |

▲ |

● |

||

| 80 |

○ |

X | X |

● |

● |

○ |

X |

○ |

▲ |

○ |

||

| 氧化铁 |

|

40 |

● |

● |

● |

● |

● |

○ |

● |

● |

● |

● |

| 60 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

○ |

||

| 80 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

||

| 硫酸 | 30 | 40 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

| 60 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

||

| 80 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

||

| 95 |

|

● |

● |

● |

● |

● |

● |

● |

● |

|

||

| 60 | 40 |

● |

● |

● |

● |

● |

|

● |

● |

● |

|

|

| 60 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

||

| 80 |

○ |

● |

● |

● |

● |

● |

● |

● |

● |

|

||

| 95 |

|

● |

|

|

● |

○ |

● |

|

|

|

||

| 98 | 40 |

|

● |

● |

|

● |

|

● |

|

● |

|

|

| 60 |

|

○ |

● |

|

● |

|

○ |

○ |

● |

|

||

| 氢氟酸 | 25 | 40 | X |

● |

X |

○ |

● |

|

● |

● |

● |

|

| 60 | X |

● |

X |

○ |

● |

X |

● |

● |

● |

|

||

| 80 | X |

● |

X |

○ |

● |

X |

● |

○ |

● |

|

||

| 盐酸+硝酸 | 31 | 40 | X |

● |

● |

X |

|

X |

● |

|

○ |

X |

| 60 | X |

● |

○ |

X |

|

X |

● |

|

○ |

X | ||

| 80 | X |

● |

|

X |

|

X |

● |

|

● |

X | ||

| 盐酸 |

15 |

40 |

● |

● |

○ |

● |

● |

X |

● |

● |

● |

|

| 60 |

● |

●

|

● |

● |

● |

X |

● |

● |

● |

|

||

| 80 |

● |

●

|

● |

● |

● |

X |

● |

○ |

● |

|

||

|

32 |

40 |

● |

●

|

● |

● |

● |

X |

● |

○ |

○ |

|

|

| 60 |

● |

● |

● |

● |

● |

X |

● |

|

|

|

||

| 80 |

○ |

● |

● |

● |

● |

X |

● |

|

|

|

||

| 氯化锌 |

|

40 |

● |

● |

● |

● |

● |

○ |

● |

|

● |

● |

| 60 |

● |

● |

● |

● |

● |

● |

● |

|

● |

● |

||

| 硫酸镍 |

|

40 |

● |

● |

● |

● |

● |

● |

● |

|

● |

● |

| 60 |

● |

● |

● |

● |

● |

● |

● |

|

● |

● |

||

| 双氧水 |

10 |

40 |

● |

● |

● |

X |

● |

● |

● |

|

● |

X |

| 60 |

○ |

● |

● |

X |

● |

● |

● |

|

● |

X | ||

| 80 | X |

● |

● |

X |

● |

○ |

● |

|

● |

X | ||

| 次氯酸钠 | 10 | 40 |

○ |

● |

● |

○ |

● |

X |

● |

|

● |

|

| 60 |

▲ |

● |

● |

▲ |

● |

X |

● |

|

● |

|

||

| 80 | X |

● |

● |

X |

● |

X |

● |

|

● |

|

||

| 醋酸 | 25 | 40 |

● |

● |

● |

● |

● |

● |

● |

|

X |

● |

| 60 |

● |

● |

● |

● |

● |

● |

● |

|

X |

● |

||

| 80 |

○ |

● |

● |

● |

● |

X |

● |

|

X |

● |

||

| 氰化铜 |

|

40 |

● |

● |

▲ |

● |

● |

● |

● |

|

● |

● |

| 60 |

● |

● |

▲ |

● |

● |

● |

● |

|

● |

● |

||

| 80 |

|

|

|

|

|

○ |

|

|

|

|

||

咨询热线

400-887-9383